Common Mistakes

Six Retrofit Mistakes to Avoid

The following are common mistakes we see during retrofit construction. Also, a reminder that no construction should be started until the homeowner has received EBB’s approval to begin.

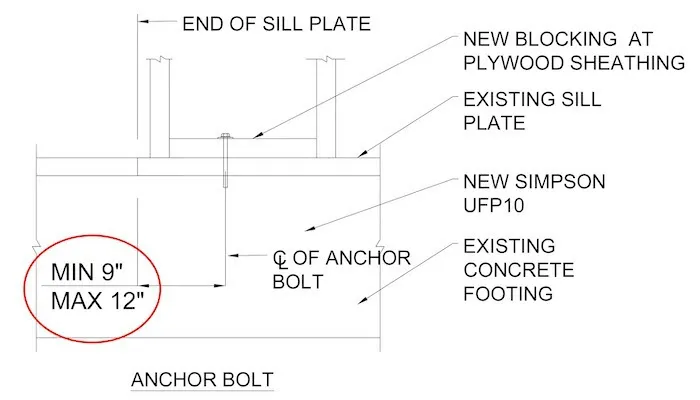

#1 Incorrect Bolt/screw end distance in mudsill

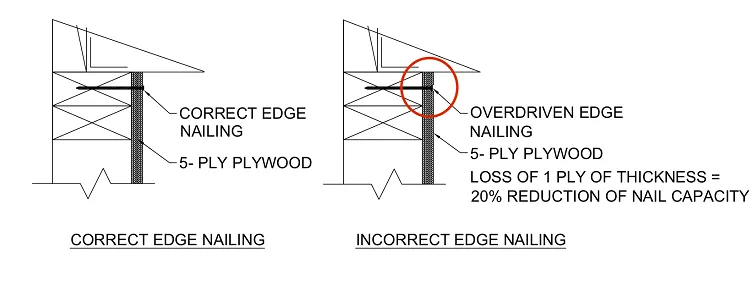

#2 Nails overdriven or misplaced

#3 Bolts and nuts improperly installed

Bolts should be straight and all nuts should be tightened as per manufacturer specifications

Bolts should be flush with the top of the nut

#4 Use of non-approved angles, hold-downs, clips and foundation plates

No work is required at the interior of the crawlspace. Hold-downs are always located at the ends of shear walls

Vertical angles have no lateral capacity and are not required by Chapter A3 or the plan sets. Note: the requirements for foundation plates include a minimum plate thickness, 2-1/2” diameter anchors and 3-1/4” diameter lag screws

#5 Cripple walls >4’-0” must be designed by an engineer or using FEMA P-1100

#6 Only Use Manufacturer Specified Concrete Anchors in Prescriptive Hardware

Bolts should be straight and all nuts should be tightened as per manufacturer specifications

Bolts should be flush with the top of the nut